Sintering Makes It Metal

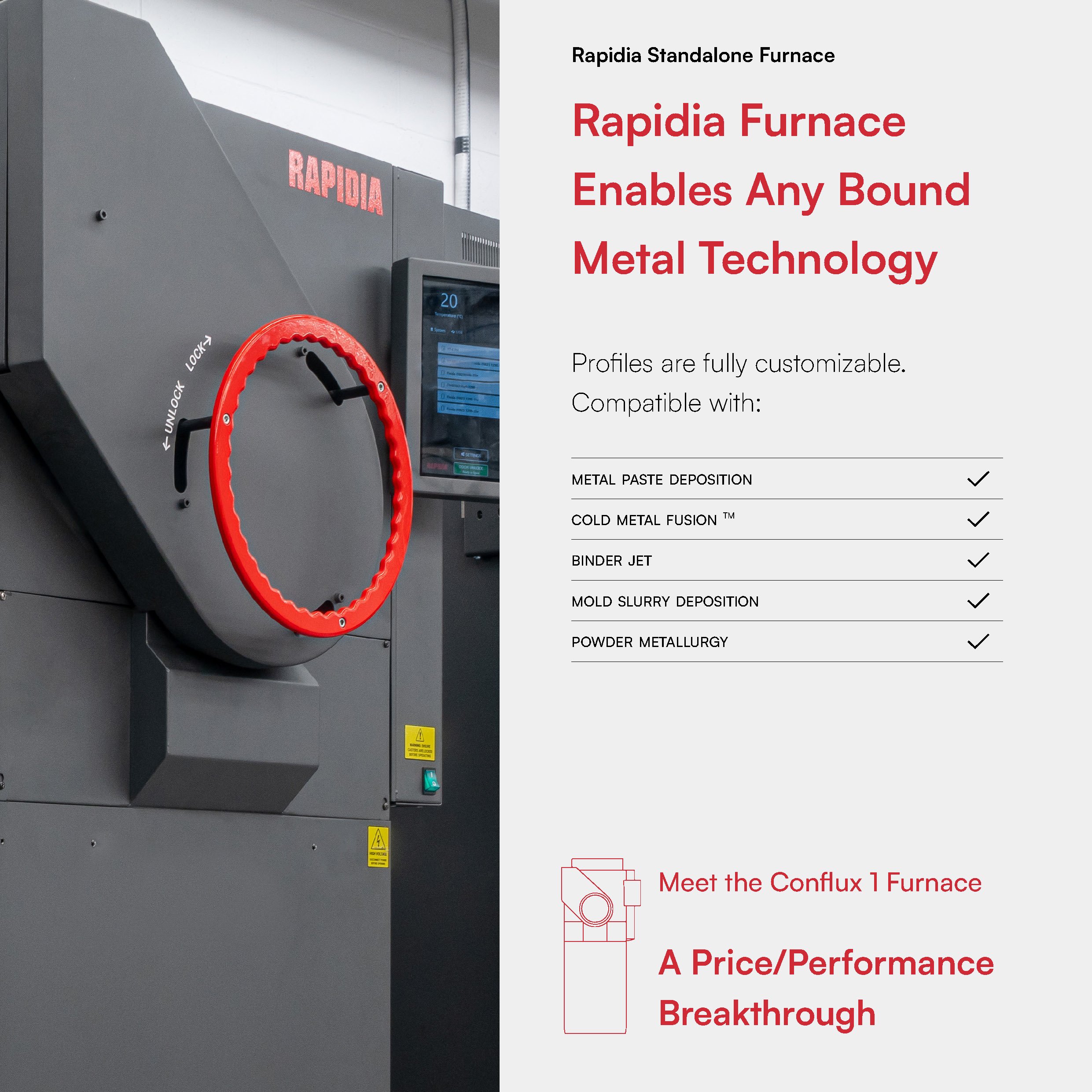

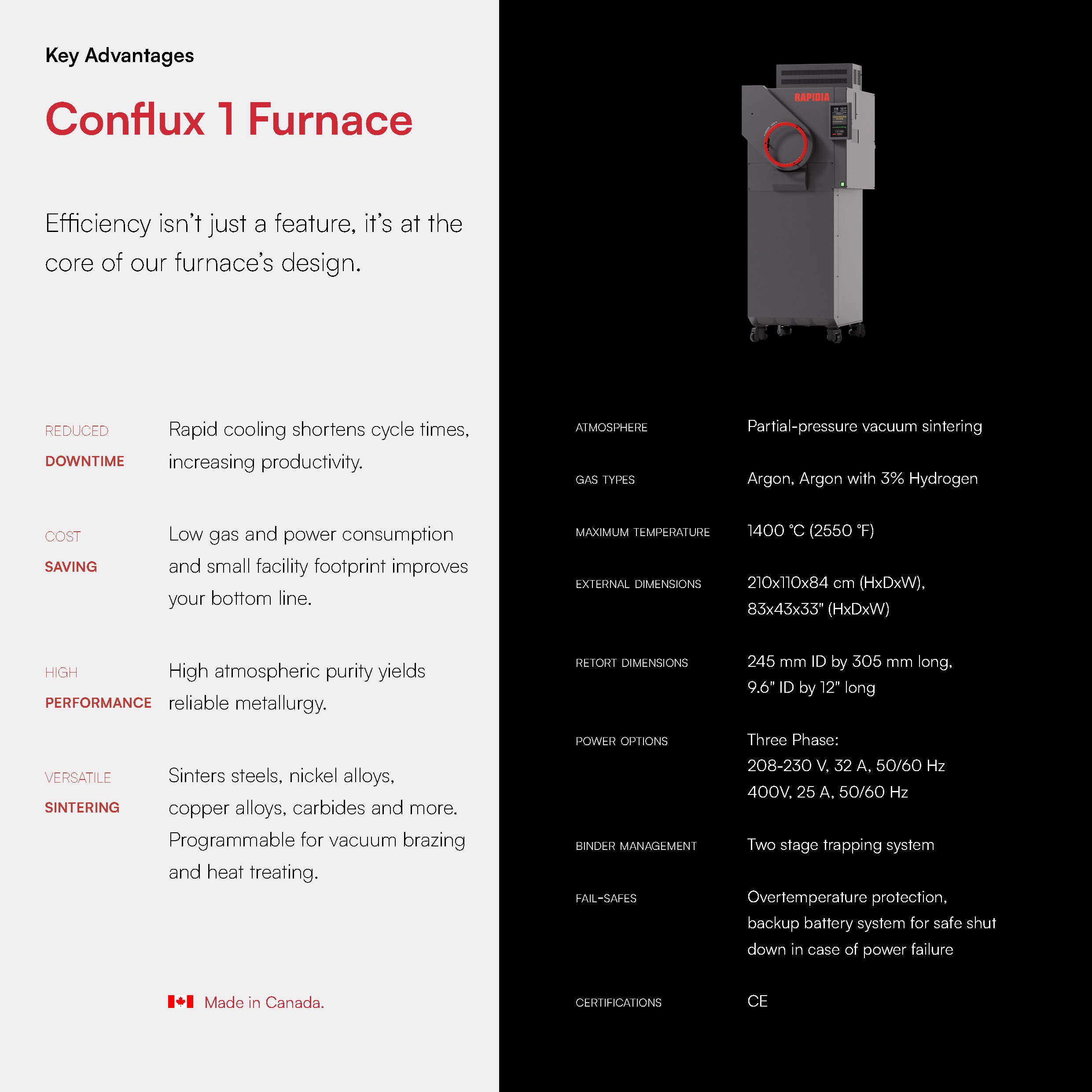

Our innovative Conflux 1 Furnace empowers any bound metal technology, offering you full flexibility and performance. Whether you're into Metal Paste Deposition, Cold Metal Fusion, Binder Jet, Mold Slurry Deposition, or Powder Metallurgy, our furnace is fully customizable to meet your unique needs.

Discover the Conflux 1 Furnace – A Price/Performance Breakthrough!

Although no booth at Formnext this year, our CEO Artem Bylinskii will be there. Connect with Artem to explore how Rapidia can reshape your metal tech.

How Sintering Makes It Metal

In the world of advanced manufacturing and 3D printing, bound metal technologies have gotten significant attention. These technologies allow us to create intricate and complex structures layer by layer.

But here’s the secret to making it truly metal:

Sintering - The CornerstoneBackbone of Bound Metal AM.

→ What Is Sintering?

Sintering is the pivotal step between a bound metal component and a fully realized metal part. It’s the process where the metal particles, held together with a binder, are heated to near their melting point to be fused and compacted into a solid, cohesive structure. Essentially, sintering transforms a concept into a functional metal piece.

→ What Is Sintering?

Binding Agents Cleanly BurnMelt Away: During sintering, the binding agents that hold the metal particles together vaporize, leaving behind pure metala porous, green part.

Metal Particles Fuse: As the temperature rises, the metal particles in the green part start to fuse together. The result is a part with increased density, strength, and structural integrity.

Shrinking to Perfection: Sintering typically involves some shrinkage, so the final part is often slightly smaller than the green part. However, the precision of this process ensures that the final dimensions match the design specifications.

→ Why Is Sintering Important?

Sintering, a quest for metal purity, isn’t just about giving metal life but also about eliminating impurities to get the desired material properties. This step is crucial in applications where material quality matters.

Our Conflux 1 Furnace is the missing piece that complements various metal technologies like Metal Paste Deposition, Cold Metal Fusion, Binder Jet, Mold Slurry Deposition, and Powder Metallurgy. It’s the tool that turns your initial parts into solid, reliable metal components.