Metal 3D Printing Platform

Conflux 1

Conflux 1 is an easy-to-use, fast, and affordable end-to-end metal additive manufacturing solution.

Powered by

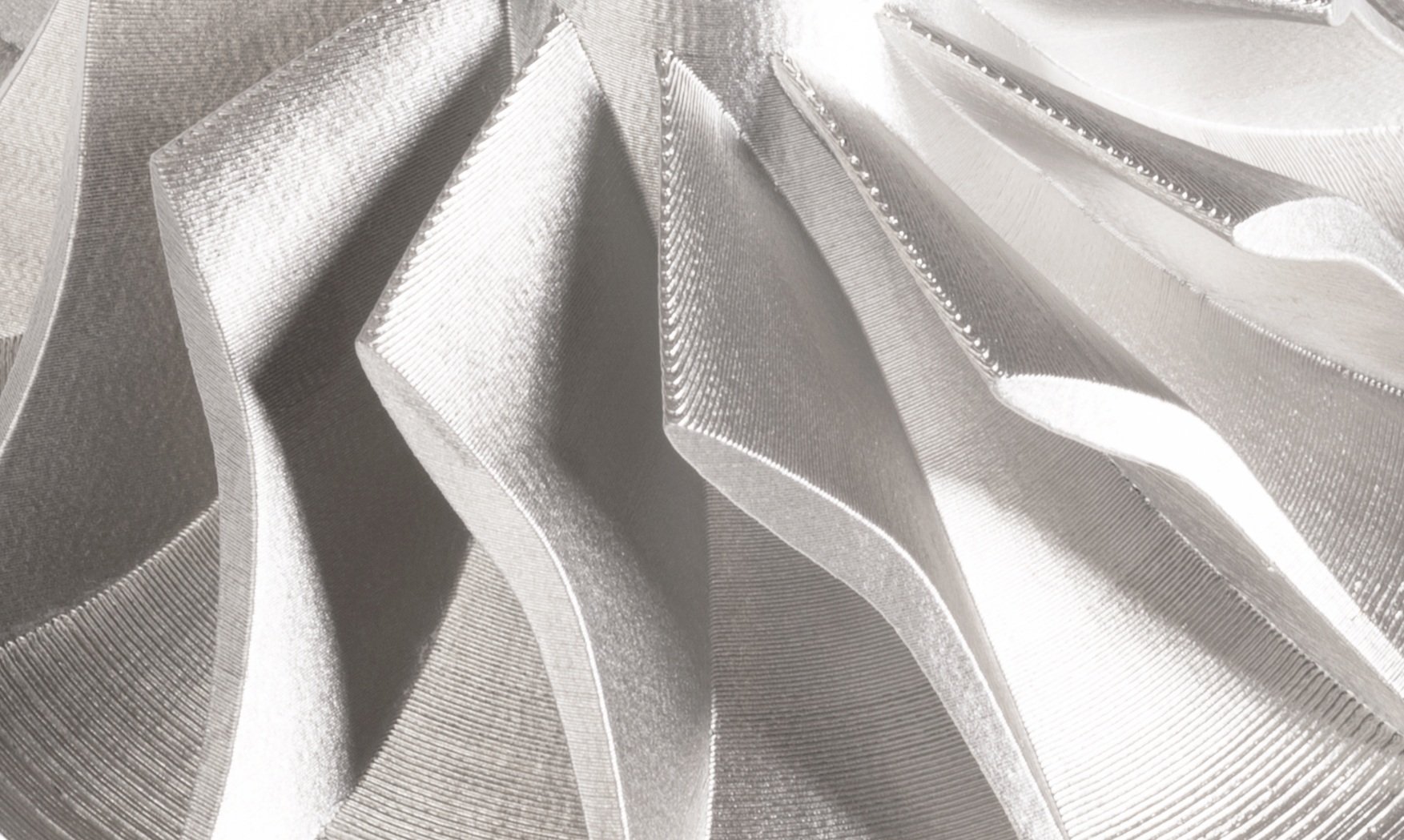

Metal Paste Deposition

Our powder-free metal 3D printing process can scale from lab-based rapid prototyping into an affordable small-scale production solution.

Conflux 1 makes

functional metal parts way faster.

Most parts are finished in less than half the time it takes to make functional parts with metal filament.

Get functional parts in under 24hrs.

Conflux 1 makes

metal 3D printing safer.

Metal that is safely bound in a paste feedstock. No chemical solvents or loose powder, no VOCs.

Make metal parts wherever you need them.

Conflux 1 makes

printing metal more affordable.

Rapidia’s system has among the lowest operating costs of any metal additive manufacturing system.

Keep low-volume part production lean and agile.

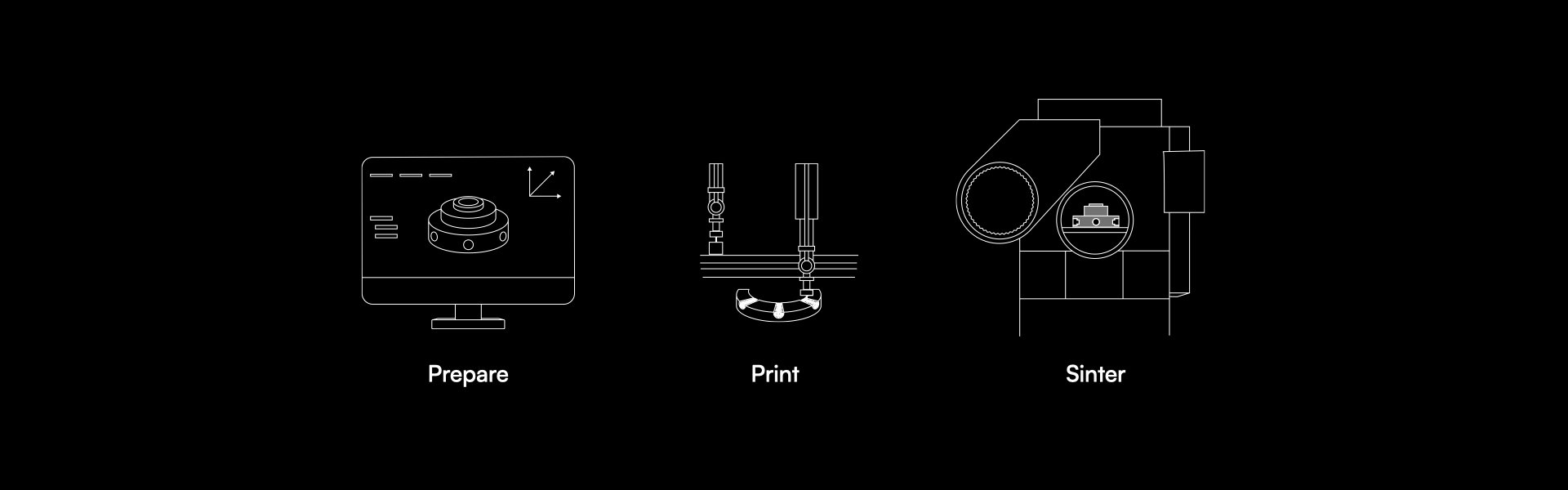

Printer to Sinter

A complete metal additive manufacturing solution

Ready to go without need for a dedicated operator and no additional equipment for powder handling, stress relieving, support removal or furnace chilling.

Conflux 1 Printer

-

Metal Paste Deposition, Independent Dual Extruder

-

1L/1000cc feedstock cartridges

Cartridge exchange program

-

~50 g / hour (316L, 17-4 PH)

-

200 mm x 240 mm x 150 mm,

7.87” x 9.45” x 5.9”

Conflux 1 Furnace

-

Partial-pressure vacuum sintering

-

Argon (standard sintering),

Argon with 5% Hydrogen (compatible) -

1400 °C

2550 °F

-

245 mm ID by 305 mm,

9.64” ID by 12” long

Scalable Industrial Additive Manufacturing

…. Just add printers!

Pair multiple printers with each furnace while maintaining full productivity.

High-efficiency sintering furnace has low sintering gas and electricity use

Sinters with standard argon gas, while achieving excellent metallurgy exceeding MIM standards.

92

62

kWh

AV. FOR 316L

RAPID CYCLE

kWh

AV. FOR 316L

EXTENDED CYCLE

750-850L

AV. GAS USAGE

400-450L

AV. GAS USAGE

Dual Extruder

Independent Dual Extruders allow Conflux 1 to print two materials in the same print. Using our Evaporative Support material in one extruder allows printing of any shape, any overhang.

Sealed Feedstock

Quick and easy materials changes. Feedstock cartridges can be stored at any fill level. Stainless steel feedstock containers are reused through our cartridge exchange program.

Easy Calibration

Rapidia Print is our print management software. It provides built-in extrusion calibration, extruder alignment, and print monitoring.

Open Platform

Prepare prints with your preferred slicer or use Rapidia Cura with added support generation tools. Slicing profiles are tuned for optimal results on Conflux 1, but all settings remain unlocked to give users full control.

Users may also create custom Conflux 1 Furnace cycles for vacuum heat treating, vacuum brazing, or specific sintering needs.

Contact Us

Contact us to discuss costs per part for your application

Materials for

your application

Check out available materials and metallurgical properties.

Conflux 1

Powered by Metal Paste Deposition