3D Printing

Materials

Advanced materials

for your application

Our growing materials portfolio includes several metals as well as an evaporative support material to unlock impossible part geometry and eliminate the need for support removal processes. Check out our available materials and materials in development below.

Qualified Material Datasheets

In Development

Copper (beta release available) H13 Tool Steel

Cemented Tungsten Carbide

Support Material

Our Conflux 1 printer has dual extruders which allows the printing of evaporative support inside and outside any metal part. Evaporative support serves two purposes:

1 - Design Freedom

Allows printing of any overhang.

Metal Paste Deposition can print overhangs up to 45° without printed support. Using evaporative support in the second extruder allows any overhang, including completely horizontal overhangs, to be printed on Conflux 1.

2 - Easy Removal

Functions as a release layer between metal surfaces.

Since cantilevered shapes are prone to sag during sintering, it is often helpful to print metal supports to provide support through sintering. By printing a layer of evaporative material between metal supports and the part, these supports are prevented from bonding to the part during sintering and can be removed by hand.

Metal Paste Feedstock

316L Stainless Steel

This austenitic stainless steel has excellent corrosion resistance to chemicals and harsh environments.

-

marine environments

chemical processing

food processing

biomedical equipment

pharmaceutical production

316L

When corrosion resistance is your most important criterion, 316L is a great choice. Download the material properties datasheet here.

17-4 PH Stainless Steel

This precipitation hardening martensitic stainless steel grade pairs good corrosion resistance and hardness with excellent strength. It can be heat treated to achieve a hardness of 41 HRC. It is commonly used for high stress applications.

-

Mold making

Tool making

Valves

Gears

Shafts

17-4 PH

An excellent choice to stand in for high-strength alloy steels in any force-bearing mechanical application. Download the material properties datasheet here.

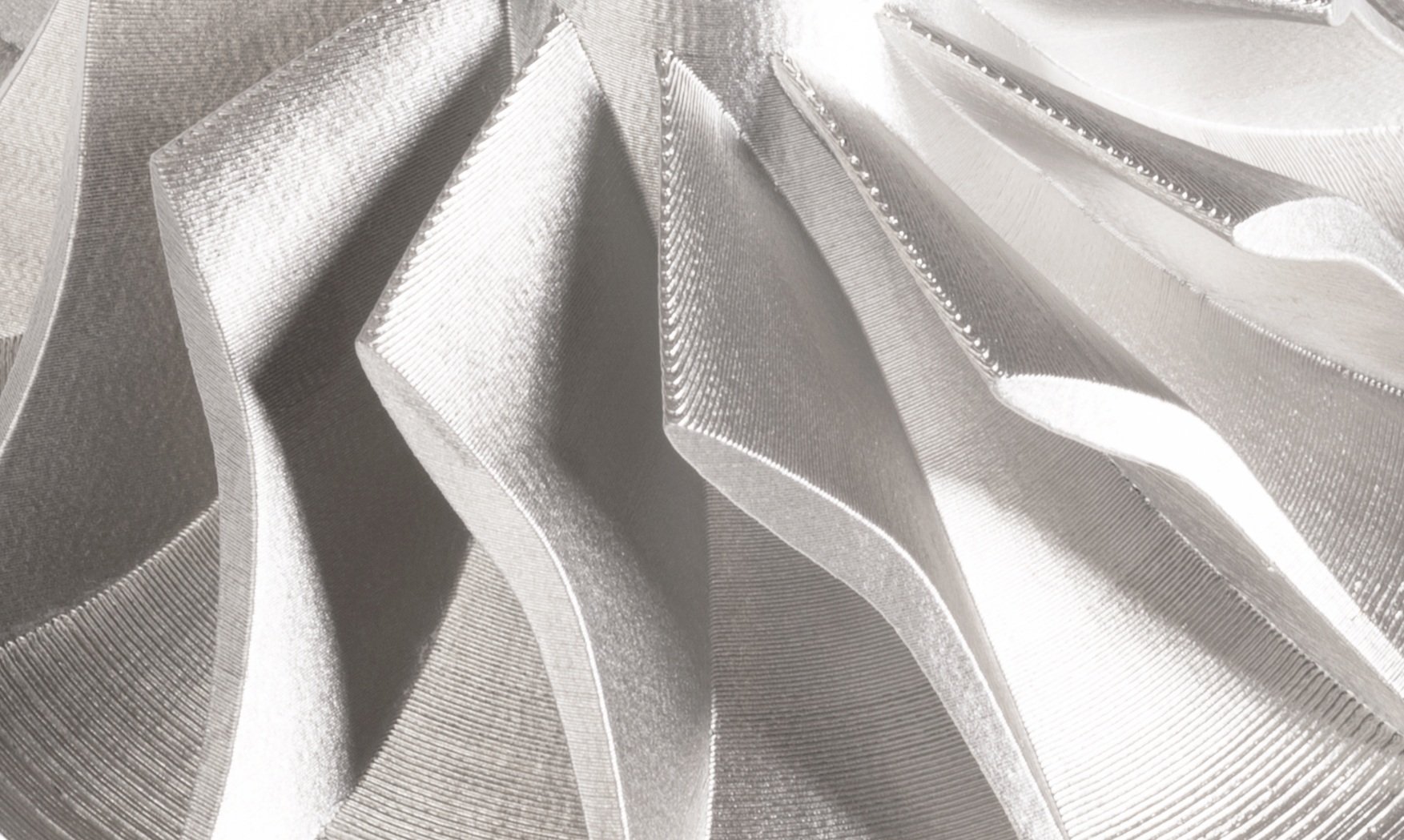

IN625 Nickel Superalloy

Commonly known as Inconel™ 625, this nickel-chrome superalloy offers extreme-environment corrosion resistance beyond that of 316L. It maintains its strength to a temperature near its melting point, making Superalloy 625 a desirable choice for high-temperature and high-pressure applications. Its extreme corrosion resistance also makes it suitable for harsh chemical and oxidizing environments.

-

Oil and gas extraction

Petrochemical processing

Pulp and paper mills

Turbine engines

IN625

IN625 is famously difficult to machine, and additive manufacturing can significantly reduce headaches in part production. Download the material properties datasheet here.

Check back frequently for updates or contact us to discuss your material needs, applications, or collaborations on custom material development.

Materials In Development

We are constantly developing new metal paste feedstocks. Materials that are actively in development are listed below.

In Development

Tool Steel

D2 tool steel is a versatile air-hardening alloy with high wear resistance. It is used for forming dies, blades, tools, molding dies, punches, and other high wear applications.

In Development

Cemented Tungsten Carbide

One of the hardest materials available for industrial use, cobalt-cemented tungsten carbide is a composite material used for the most demanding abrasive environments.

In Development

Copper

Copper is a fantastic thermal and electrical conductor. High-purity copper is used for electrical conductors, heat sinks, radiators, heat exchangers and other electrical components.

Conflux 1

Powered by Metal Paste Deposition